We may receive a commission for products purchased through the links on our site at NO additional cost to you.

Are you interested in making pieces out of wood that can be both functional and artistic? Wood turning is the art of carving wooden blocks while they spin on a lathe. The best wood lathes make it easy for beginners to learn quickly and for the seasoned carpenter to create elaborate works of beautiful complexity. Simply shave layers away from the wood quickly with great precision. With tons of different options available, it can be hard to know the best woodworking lathe for your needs. Fear not, here you will find our unbiased top 10 wood lathe reviews and detailed guides to let you know about the latest top models of these wood turning machines.

[go_pricing id=”best_wood_lathes1″]Best Woodworking Lathe Reviews – Top 10

1. JET JWL-1221VS Wood Lathe

A professional grade mini-lathe that handles the heaviest jobs with a 1 horsepower motor. This lathe has unique variable speed drive with one of a kind ratchet style belt tension system.

Offering digital speed control with reverse options. To change speeds simply turn the knob and wait for the digital readout to hit the magic number. The change to reverse is equally smooth. The Integrated spring loaded spindle lock and 24 indexing positions help make it look easy.

This is a lathe for the experienced turner or for the beginner who wants to jump with state of the art equipment. The powerful motor can make the most of the extension systems offered by Jet.

The 12.5 inch swing combined with the speed control creates a lathe that is perfect for bowls as well. The power, speed control, and capacity of this lathe makes it a leader in this competitive pack of tool.

Pros:

- Power: Strong build with a 1 HP motor that will turn anything that fits on the lathe.

- Speed control: This lathe is redefining speed control with an unparalleled range of speeds between 60 to 3,600 RPM.

- Capacity: The 12.5 inch swing is top in it’s class with a 20.5 inch long center to center distance.

- Easy to use: Once you have dialed in how fast you want the piece to turn you can set the speed and work with confidence.

Cons:

- Accessories: Does not come with a lot of tools. You will need to pick up the accessories and tools separately.

- Quality control: There have been several reports of lathes shipping out with cracked frames or head bearings.

2. Delta Industrial 46-460 Midi Wood Lathe

The Delta Industrial midi lathe is just that, an industrial tool that has the power and the build to tackle heavy jobs. With a full 1 horsepower motor.

The distance between centers is 16.5 inches long and the extension brings that up to 42 inch and with this lathe, you won’t have to worry about it bogging down.

The electronic variable speed control and smooth transition to reverse help in making your job enjoyable and easy. With their patent pulley system you won’t have to keep up with multiple belts. It also has 24 indexing positions to help in intricate designs.

As is becoming the trend they added a few extras to help get you started right away. There is a 6” and a 10” tool rest, a chrome 3” face plate, tool rest base, knockout bar, live center, and a few wrenches to adjust the belts.

Pros:

- Power: Cast iron lathe packed with a 1 HP motor to give the confidence and power you need for big projects.

- Speed control: Decide what speed you want and have the safety of controlling it between 250 to 4,000 RPM.

- Capacity: 12.5 inch swing over the base provides a large capacity for many projects.

- Tool suite: 5 year limited warranty and some great tools to get you started right away adds to the value of this machine.

Cons:

- Electrical inconsistencies: The switch will likely be wired backward. If you’re lucky that’s all that you will need to fix.

- Tool rest: They will need to fit into 5/8 inch fitting instead of standard 1 inch.

3. Nova 46300 Comet II Wood Carving Lathe

The Comet II is a solid choice for a wood turning lathe. It boasts 12 inch swing and 16.5 inch long between centers which can be extended to 41 inches with an attachment.

The 3/4 horsepower motor works with three pulleys to produce maximum torque or speed depending on what is needed. There is a readout for the variable speeds range from 250 RPM to an impressive 4,000 RPM.

It comes standard with 1″ – 8 TPI thread, 3″ faceplate, hand wheel, 12 point index, 6″ tool rest, 2MT drive center, 2MT live center, and knockout bar.

The most interesting thing about the Comet II is the grinder attachment. This clever combination may give you the extra bench space you need for the extension. In any case, it’s a space and money-saving feature that doesn’t exist anywhere else.

Pros:

- Power: The 3/4 hp motor gets the job done on most jobs thanks to the efficient belt system.

- Speed control: Once you have dialed in how fast you want the piece to turn you can set the speed and work with confidence.

- Grinder attachment: Unique feature that makes turning more fun and easy by allowing you to sharpen your tools.

- Value: This amount of torque and versatility offers great value at the current price point.

Cons:

- Build: Parts tend to break down under heavy use. Patience is advised on heavy jobs. Also, some have complained there are sharp machined edges on the lathe. Some sandpaper can help.

- Narrow: It doesn’t take up as much bench space as some of its competition but that makes it feel a bit less stable when turning big pieces or while off center.

4. Grizzly H8259 Woodworking Lathe

The Grizzly H8259 is a great entry level wood lathe. It has a sturdy built equipped with a 1/2 horsepower motor. Features a 10 inch swing which is good for a variety of tasks from pen turning to some bowl work.

There are five speeds on this lathe 826 RPM, 1205 RPM, 1713 RPM, 2422 RPM, and 3337 RPM which can require patience for turning rough or unbalanced pieces. However, the solid construction and sturdy built is to praise, there is minimal vibration, if any. Allowing you to accomplish top-notch precise designs.

It comes with tool rest, faceplate, live rolling center, spur center, and wrenches. With limited speed control and range this lathe is best suited for pens and other small work over the 18 inch bed.

Ultimately a good wood lathe for someone who loves crafting small objects.

Pros:

- Power: Solid machine, build to last. The 1/2 HP motor will keep spinning with you for years to come.

- Speed control: Provides five different speeds to choose from to match your work.

- Capacity: For a mini wood turner, 10 by 18 inch swing capacity is enough for a variety of projects.

- Accessories: Has MT2 spindle and taper which accommodates a many useful attachments.

Cons:

- Runs hot: You may need to give this thing a rest over large projects

- Price: Several lathes in the same price point offer more features.

5. WEN 3420T Mini Wood Lathe

This is a great introductory mini lathe, loaded with features. It comes with variable speed adjustment, Morse taper #1 for the spindle and tailstock to firmly hold your stock, two tool rests 4-1/2″ and 7″, and a 5″ faceplate to spin non spindle work such as bowls or cups. It even comes with a headstock center spur, a tailstock center cup, a flat wrench, and a knockout rod.

Has a user friendly lever clamping mechanism that makes adjustments precise and easy to both the tool rest and the tailstock. This lathe is for someone new to woodturning or who do not turn big or rough pieces. Features a soft start motor and a safety lock to make any novice feel more comfortable turning the machine on for the first time.

The speed control is easy to use with a good range of speeds. The small 2 amp motor is best for small works, however, the bed offers versatility by allowing pieces as long as 12 inches and as wide as 8 inches.

Pros:

- Power: The 2 amp 1/3 HP motor is smooth and runs very quietly.

- Speed control: Between 750 to 3,200 RPM, simply turn the control until the speed feels right.

- Value: Great value for the money, ideal for people who are just starting out with wood turning.

- Versatile: Comes with almost everything to get you started.

Cons:

- Not enough power: Projects will have to remain small and tools will have to stay sharp or this lathe will become frustrating very quickly.

- Quality: You are getting a lot for your money but that spreads your money thin. The included accessories can be finicky and don’t necessarily compete with their aftermarket counterparts.

6. JET JWL-1440VSK Floor Standing Wood Lathe

A versatile floorstanding wood lathe from JET tools, designed to meet different wood carving tasks. Equipped with a 1 horsepower motor, variable speed control, a pivoting head, and much more.

The powerful motor and the large swing capacity available on this lathe makes it suitable for wide bowl turning, as well as, long spindle turning. Aggressive cuts or low speed resistance is not a problem with this machine. It also has 36 indexing positions.

Not to mention the sliding/pivoting headstock has 7 locking positions from 0, 30, 60, 90, 120, 180, and up to 270 degrees. This gives you the ability to work with stock as large as you can imagine. This updated model also comes with improved tailstock locking.

It has a sturdy cast iron stand that makes fitting large stock a simple process. The variable speed drive is easy to use. Simply, turn a knob at the front of the headstock to smoothly change the speed.

Pros:

- Power: Cast iron heavy duty construction for an anti vibration free standing design, weighs 352 pounds, packing a 1 HP motor.

- Speed control: Easy adjusted speed control from 400 to 3,000 RPM, equipped with a digital LCD display.

- Capacity: Has a large 14.5 inch swing capacity coupled with a 40 inch center distance. Adding to that the sliding and 360 degrees pivoting headstock, thus, unlimited stock sizes.

- Reliability: The machine is backed by a 5 year limited warranty, which only shows the trust the manufacturer has for their product.

Cons:

- Speed knob: The speed knob works great on high speeds, however, it felt a bit resistant at low speeds.

- Value: It comes with a big price tag, though, that is to be expected with a lathe of this size.

7. Rikon 70-220VSR Woodturning Lathe

This is a step up for the midi wood lathe enthusiast. The 1 horsepower motor brings all the power you need for this versatile machine. The variable motor has three speed settings (250-750 RPM, 550-1650 RPM, and 1300-3850 RPM).

Has 12.5 inch swing allows for some bowl work, and the 20 inch center distance it’s suitable to produce some great spindle work as well. It comes with forward and reverse drives and 24 indexing settings. In addition, a tool rest, 3″ faceplate, live center, spur center, and wrenches giving some extra value for this lathe.

Designed specifically for those who are serious about turning detail-oriented work on a regular basis. The powerful motor and electronic variable speed make this lathe versatile enough for beginners and professionals alike to remain joyfully occupied for hours.

Reliability and consistency are the hallmarks of this wood lathe and this machine is sure to keep you focused on woodturning projects.

Pros:

- Power: Rikon’s high quality built fitted to a 1 HP motor, expect reliability and durability.

- Speed control: Great variable speed range with a digital readout, ranging between 250 to 3,850 RPM.

- Capacity: The 12.5 swing is a step above the competition coupled with the 20 inch center distance.

- Reliability: Rikon offers a limited five-year warranty more than doubling a lot of the competition.

Cons:

- Slowing down: You may find it slowing down a little if you get too aggressive with it.

- Power switch: The on/off power switch is awkwardly placed, it makes easy access a bit difficult.

8. PSI Woodworking KWL-1018VS Turncrafter Commander Lathe

The Turncrafter Commander is the balance between power, build, and economy. The 3/4 horsepower motor gives it more control than a lot of its competition, and it comes with a lot of the starter tools that the more powerful and expensive models leave out.

The variable speed belt drives deliver an excellent range of 500 to 3,600 RPM, and the digital readout makes it easy to know you are on the right path.

It has built-in handles and 24 index positions with a spindle lock. There are some thoughtful things provided like the tool rack storage and the 6″ and 12″ tool rests which are nice for those first time woodturning.

There is also safety goggles and work light with 18″ flex cable, a 3″ faceplate, spur drive center, and tailstock live center. Lastly, the hex wrenches you will need for change the belts.

Pros:

- Power: Great value for the money, comes with a 3/4 HP, offers more power than most of its competition.

- Speed control: Has a digital readout and multiple belt drive to give a good speed range.

- Capacity: Offers a 10 inch swing and 18 inch center to center distance.

- Features: This is a well thought out lathe with everything you need but a chisel and wood stock.

Cons:

- Quality of tools: The lamp and other tools are not going to stand up like quality aftermarket brands.

- Quality control: Take pictures of your kit as you take it out making sure that everything is in place.

9. Shop Fox W1704 Benchtop Wood Lathe

With an 8 inch swing and 13 inch center, it’s small yet powerful enough to create beautiful designs. Equipped with the same 1/3 horsepower motor, similar to the WEN model.

This benchtop wood lathe is for beginners with sharp tools. It comes with a comprehensive set of starter attachments; a safety power switch, MT #1 spur and live centers, two tool rests, a flat wrench, and a knock out rod.

It has a cast iron strong construction and can comfortably sit on top of your work bench. Out of the box, this lathe is very hard to distinguish from the WEN model. With almost the same specifications and suite of starter tools.

It may be best to look for both the Shop Fox and the WEN and see which carries better features and value for you. Compare the price, the accessories, and all round features.

Pros:

- Power: Cast iron construction and has 1/3 HP motor.

- Speed control: Just turn the knob until the wood turns at the right speed for you, ranging between 700 to 3,200 RPM.

- Quiet performance: Efficient and quiet, lets you spin away.

- Value: A wood lathe with a lot of accessories for getting started.

Cons:

- Not enough power: Projects will have to remain small and tools will have to stay sharp to easily accomplish your projects.

- Limited function: The capacity and range of features create more excitement than the motor justifies, makes it hard to get a good learning curve.

10. Goplus Power Full-Size Wood Lathe

This variable speed belt driven lathe is an entry level for beginners who want to experiment with a full-size wood lathe, it gives you the freedom to work on long designs such as table legs and much more.

The 1/2 horsepower motor has enough oomph to knock out medium size jobs with a little patience. The 14 by 40 inch capacity allows for large projects. The steel frame makes the lathe easier to set up than some of the heavier competitors that are made of cast iron.

This lathe is the bare bones. If you do not need a lathe very often, or you just want to turn a little wood before you lay out the big bucks this can be a good option. The capacity allows for some exciting projects while the speed controls allow you the flexibility to work on a variety of items.

This lathe does not come with any accessories like tool rests, however, there is a variety of add-ons available online.

Pros:

- Power: The 1/2 horsepower motor is suitable for light to medium sized projects.

- Speed control: Offers 4 adjustable speeds 1100 RPM, 1600 RPM, 2300 RPM, and 3400 RPM.

- Capacity: The 14 inch swing is impressive, well matched with the 40 inch center distance.

- Ergonomic design. The price point is great, you can’t find another lathe this size for the same price tag.

Cons:

- Unmatched: The small motor does not equal the potential of the large capacity.

- Vibration: The lightness of the frame can cause more vibration if the wood is not perfectly symmetrical or centered correctly.

- Belt design: Requires turning the machine off to change speeds.

Best Wood Lathes Comparison

| Product/Feature | Input | Speeds | Reverse Drive | Index Positions | Tool Rest | Face Plate | Dimensions |

|---|---|---|---|---|---|---|---|

| JET JWL-1221VS | 120V, 1PH, 60Hz | 3 Speed Ranges | Available | 24 | 6" - 10" | 3" | 33.6 x 11 x 17.7 In. |

| Delta 46-460 | 120V, 1PH, 60Hz | 3 Speed Ranges | Available | 24 | 6" - 10" | 3" | 36 x 11 x 17.8 In. |

| Nova 46300 | 120V, 1PH, 60Hz | 3 Speed Ranges | Available | 12 | 6" | 3" | 33 x 9 x 18 In. |

| Grizzly H8259 | 120V, 1PH, 60Hz | 5 Fixed Speeds | N/A | N/A | 6" | 3" | 36 x 11.5 x 15 In. |

| WEN 3420T | 120V, 1PH, 60Hz | Variable | N/A | N/A | 4½" - 7" | 5" | 26 x 10 x 12 In. |

| JET JWL-1440VSK | 120/240V, 1PH, 60Hz | Variable | N/A | 36 | 12" | 3" | 74 x 18 x 49 In. |

| Rikon 70-220VSR | 120V, 1PH, 60Hz | 3 Speed Ranges | Available | 24 | 8" | 3" | 12 x 40.8 x 17.6 In. |

| PSI KWL-1018VS | 120V, 1PH, 60Hz | 2 Speed Ranges | N/A | 24 | 6" - 12" | 3" | 32 x 9 x 17 In. |

| Shop Fox W1704 | 120V, 1PH, 60Hz | Variable | N/A | N/A | 4¼" - 7" | 5¾" | 7.1 x 27.9 x 13.7 In. |

| Goplus SU-31188-LT | 120V, 1PH, 60Hz | 4 Fixed Speeds | N/A | N/A | N/A | N/A | 57.2 x 9 x 14.9 In. |

6 Steps to Help You Choose the Best Wood Lathe

Selecting the best rated wood lathe can be challenging. Research is the key to finding the perfect tool for your upcoming projects. Even if you have been turning wood for a long time, it is still important to read the newest wood lathe reviews to know how the latest models are performing and what new features are available. If you are new to wood turning it is especially important to get a good understanding of what your potential lathe is capable.

To find the best wood lathe for beginners, there are several things to consider. What are you making? What kind of wood are you using? And what is your workspace like? By considering these questions you will determine the size, power, and build of your lathe and determine what features it must have. In this guide we will focus on hobby and light industry use lathes but the same options apply to all sizes. You should again consider the size of your projects before deciding on which will be the best wood turning lathe.

-

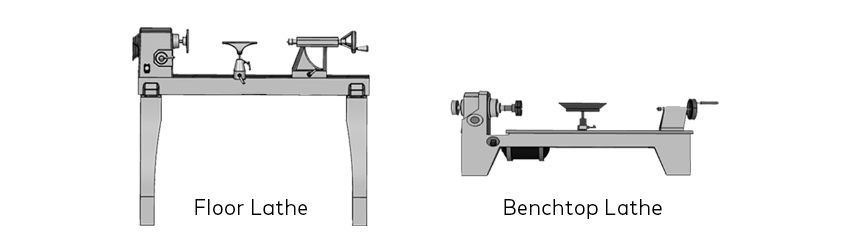

Base Bed

Finding the right lathe for your space is very important. When it comes to sizes, we can put all lathes into two major categories: tabletop lathes and lathes that rest directly on the ground. Tabletop/benchtop wood lathes are lighter and more portable than standing wood lathes. However, floorstanding lathes hold larger capacities for supporting large workpieces.

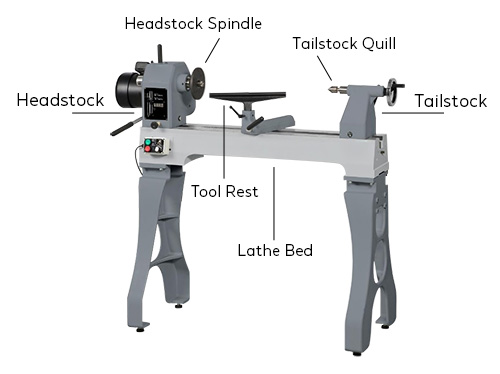

Either way choose a lathe with a heavy-duty (preferably cast iron) base. The base is the main platform where all the lathe components rest. You want it to be sturdy and strong enough to support the wood and the rotating motor, while keeping vibrations down to a minimum. Just a bit of vibration can make turning difficult and unsafe. Thus, the heavier the build, the better.

Also, the bed is another important factor to consider. The bed is the polished stainless steel beam where all the moving parts are mounted. If your project has larger diameters, pay attention to the length of the bed. If the lathe is to be anchored to a tabletop or secured to the floor consider the height of the legs. The lathe’s spindle should be around the same height as your elbows while you are standing. This provides most comfort and practicality during work, we will get more into that in the next section.

-

Capacity

The swing is the maximum dimensions of wood that can fit in your lathe. To know these measurements you need to check three main things: swing over bed, swing over rest, and center to center distance.

-

Swing Over Bed

This refers to the maximum thickness of stock that you can turn without hitting the bed. If a wood lathe is rated 10 inch swing over bed, it means that the distance from the bed to the spindles is 5 inches. So the largest diameter that you will be able to turn is 10 inches. Consequently, the higher the number, the wider the stock. Additionally, some wood lathe models come with a rotating headstock that allows it to swivel to 180 degrees. Allowing you to spin larger stock such as turning bowls with no bed limitation.

-

Swing Over Tool Rest

This value represents the maximum thickness of stock you can turn without hitting the tool rest. The tool rest is an adjustable short stand that slides along the bed to give you access to any part of the workpiece. It provides a stable place to rest your shaping tool (for example chisel) while turning your workpiece. Most lathes do not come with a tool rest but it’s important to note the capacity of the swing over tool rest if included.

-

Center to Center

Center to center distance is the measurement between the head and tail spindles. This refers to the maximum length of stock you can fit on your lathe. If the center to center distance is 30 inch, it means you can spin maximum 30 inch long workpieces. Thus, the higher the number, the longer the stock. Longer distances allow you turn table legs, chair legs, baseball bats, and much more. Some lathe models offer length extensions, but you should not rely on an extension for every day work.

-

Power

Larger pieces like table legs and banisters require some umph. The weight and size of your wood will determine how much horsepower the motor should have. The bigger the wood the more horsepower needed to support turning these large pieces at a constant speed. Motor sizes range from 1/8 up to 3 horsepower and more.

The most common size for hobby and home use is between 1/3 to 1 horsepower, though more torque and power is always welcome. In this range you can turn bowls, furniture legs, and decorative objects. But if you are interested in turning really big projects or if turning heavy wood is all you will do then you may enjoy the confidence that one of the great 3 horsepower machines offer.

Regardless of the motor though each machine performs differently. So the horsepower is only a good starting point when comparing different models.

Additionally, it’s important to check the voltage. Standard lathes require either a standard 120v plug or 240v plug. Lower voltage options are more versatile, while higher voltage options give more power. The important thing to consider here is the wiring in your work areas. So it’s important to note the voltage, full load current, and phase.

-

RPM Speed

The speed requirements will be set by the type and shape of wood you are starting with and the complexity of projects you want to complete. Certain projects will require multiple speed options and reverse drives so it is important to understand what techniques go into creating the project you have in mind before making your lathe purchase.

A good wood lathe comes with 4 or 5 speed levels. A good set of speed range is between 200 to 4,000 RPM. Slower speeds between 200 to 800 can be used for sanding, shaping, applying oil to your finished workpieces. While for example turning table legs demands fast rotation.

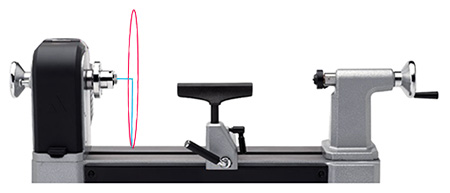

The revolutions per minute (RPM) here represents the spinning speed of the spindle. To calculate the maximum and minimum ballpark RPM speed for woodturning, follow the below equations:

9,000 divided by the diameter (D) of the workpiece = Maximum RPM

6,000 divided by the diameter (D) of the workpiece = Minimum RPM

So, for example turning a 5 inch diameter workpiece will require between 1,800 to 1,200 RPM.

-

Speed Changing System

There are different mechanisms that control the speed of lathe machines, so it is important too look past the maximum and minimum speed and see which speed control mechanism is right for you as well. There are three main types of speed mechanisms for wood lathes.

-

Belt Drive

This is the most basic method. In order to adjust the speed, the belts need to be changed manually. The belt drive lathes have presets that prevent you from changing the speed while the machine is turned on. You can adjust the speed, but only to predetermined settings. The speed range is somewhat limited and they typically come with 3 pulleys.

-

Variable Speed

This is the easiest option for changing the speed. Once the belt is set, you can then adjust and control the speed with a simple dial. Generally, they offer about five speed pulley levels to choose from. While the more modern, best variable speed wood lathes come with an unlimited speed range. Offering a wide range of speed selection from as low as 60 RPM (sometimes less) and up to 4,000 RPM (and higher). They also allow you to adjust the speed without turning off the machine. Additionally, they come equipped with LCD display to make it even easier to monitor the selected speed.

-

Gearhead

These also allow adjustable speeds during operation, but these are falling out of favor because a lot of them are very loud, especially at high speeds. Gearhead lathes are more common in large-scale and industrial use as they offer the largest capacities.

To sum it up, a belt drive is the most budget friendly. While variable speed lathes offer ease of use and flexibility. After all, it’s up to you to decide on which is more suitable.

-

Essentials

Your lathe does not come with everything you need. The extras matter no matter what you plan on building.

- Tool rest: one of the most important essentials in a lathe. There are several options for basic models in terms of length. Also, some are made with a slight curve that acts as a hand rest. Modular systems allow flexibility at a good value.

- Power switch: an easily-accessible on/off power switch can be an overlooked feature. However, switches located in hard-to-reach places can be a safety hazard.

- Slow start: this allows a lathe motor to initially start at low speed regardless of the preset speed. This safety feature gives you the time to make sure the workpiece is properly fastened before accelerating.

- Reversing option: delivering both forward and reverse gears for turning. This gives you the ability to do the finishing of your piece both with and against the grain of the wood.

- Indexing positions: this gives you the ability to make intricate designs on your workpieces. This involves locking your stock onto the headstock spindle at different positions.

- Grinder wheel: a small grinder attached to the lathe. This gives you the luxury of conveniently sharpening your hand tools.

- Accessories: for the widest variety of accessories, a lathe that has a standard taper size is important. For example, Morse taper #2 (MT2).

Finally, it’s all about the possibilities. Maybe you will make a bowl that will make someone think of you every morning at breakfast or you could carve out the bat your nephew uses to hit his first game. Try to focus on what you want to make and what you have at your disposal and go from there. Stay current on woodturning lathe reviews and make sure you pick out a lathe that your workspace can accommodate.

Most Important Wood Turning Lathe Attachments

When deciding on the right wood lathe it is important to factor in the essential wood lathe attachments for the projects you want to complete. When you are selecting a lathe, you are buying only the machine. Some retailers will have attachments included with the lathe in a bundle so compare the prices and see if the bundle is a real value. Sometimes purchasing a stock lathe and attachment separately is the best deal. If ordering online, do not forget to check for shipping costs. Here is a list of attachments and accessories you really should not miss.

Tool Rest

This is one of the most important parts of a wood lathe. It allows you to safely rest your shaping tool against the tool rest. It should allow you to adjust and securely lock into any position to lead your shaping tool to the wood. They should also rotate to give you access to the bottom of your workpiece.

A lot of people think that a new wood lathe will come with a tool rest, but alas it does not. The good news is that you can pick out the perfect wood lathe tool rest or tool rest set for you. There are modular options available to give multiple length options as a value. However, some woodturners prefer to have individual rests for each length they need. There are some that help with bowl turning and others that correlate to other specialties.

First, starting with a straight rest or a set with multiple sizes is a good start. Then when you focus in on a specialty you can decide if buying or making a special tool rest will help achieve the affect you are after.

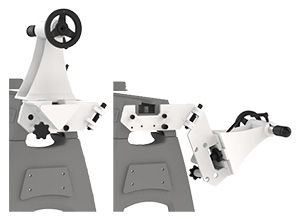

Swing Away Tailstock

An absolute must for some of the larger machines, this handy device makes it easy to load up your tail stock every time. Instead of having to bear the whole weight of the tailstock to remove it every time you want to load a new piece. Simply, the piece goes onto the end of the bed and allows the tailstock to tilt or swing out of the way while remaining attached to the bed, until it is ready to be pulled back into place. If you are working with a heavy machine or if you work with multiple pieces very often then a tilt away tailstock might be a huge time saver.

Safety Equipment

The basics for safety here are proper lighting, an eye protective glasses, a respirator, and gloves. The first you may have not considered. You need to be able to see what you are doing. Also you need to protect your face and your lungs bare minimum. You really should not even turn on the machine until you have these items. It is important to stay out of the line of debris, but unexpected things can happen and being prepared will make all the difference. It should probably go without saying that any wood shop also needs a first aid kit. If your lathe is loud you should invest in ear plugs. Not to mention, extra credit is available for dust collection systems, they are really important for every woodworking shop.

Overall, there are a ton of other fun add-ons to make this old machine do new tricks. Bed extensions for those extra long pieces and swivel headstocks for bowls as wide as can be imagined. Others just keep wood turning fun. For example: if you are using chisels then a good grinder to keep them sharp will be paramount. Nothing is less fun than turning with dull equipment! The more you work with your lathe the more obvious it will become which attachments will create the best wood carving lathe experience for you.

What is a Wood Lathe?

A wood lathe is one of the most creative and fun to use tools in any woodworking shop. It is made up of a long heavy bed typically made of cast iron or similar metal that is anchored to a tool bench/table or supported by legs that look like sawhorses. On the left side there is a headstock that connects to a low horsepower electric motor. The motor is often capable of spinning a piece of wood several thousand times a minute. The tale stock sits opposite to the headstock on the metal bed. It is capable of sliding back and forth across the bed and locking down in place to create another anchor to ensure wood does not fly off the lathe when spinning at high speeds.

A carpenter or “woodturner” centers a wooden block or “blank” between the head and tale stocks and ensures it is firmly in place. When the motor turns on, the blank will begin to spin at an incredible rate. The woodturner will then use razor sharp gouges and chisels to slowly work away layers of wood to create the desired shape. The end product could be anything from a simple writing pen to elaborate spindles for banister railings.

Wood-Turning History

Wood lathes have a unique place in history. They are often called the mother of all machines. The earliest forms were developed by Egyptians. Bow and strap lathes that were operated with two or more people were utilized in Rome and China. Eventually belt drives improved these simple machines. The belt drive enhancement is what earns the lathe its title as matriarch of machines as consequent machines were developed specifically because the belt drive already existed.

Types of Wood Lathes

Wood lathes come in several sizes and varieties. In general, we can divide them into two main types: floor standing and benchtop. The potential of each kind of lathe is really the imagination of the carpenter. The most feature driven lathes will come with debris shields, and other features to make the machine more safe and fun to use.

-

Benchtop Wood Lathe

Available in mini and midi-sized lathes. They are designed for wood crafters or light industrial use. They pack many benefits of a full-size lathe, yet, they are more compact in size. Benchtop wood lathes sit on top of your work bench and they come with predrilled holes in their stand that allows you to bolt the lathe to the bench to prevent any movement due to vibrations.

-

Floor Wood Lathe

Available in midi and full-sized lathes. This type comes with it’s own freestanding base. They are larger and pack more power. They are designed for heavier pieces or serious commercial use. The spectrum does swing all the way up to gigantic custom made machines used for industrial projects.

Overall, choosing a bench-top or a floor-standing model depends on the available space in your workshop, what you are planning to spin, and your budget.

Sizes of Wood Lathes

After we got to explain the different types of lathes. Now we can move on to explain their sizes. Lathes vary in size greatly, there are the miniature micro lathes and there are the huge industrial lathes. In general, we can divide them into three main sizes: mini, midi, and large full size.

-

Mini Wood Lathe

As the name suggests, this is the smallest size of lathes. Typically, a mini lathe will have an engine less than 1 horsepower. And can turn stock less than 20 inches long and 12 inches wide. A mini wood lathe is great for turning smaller objects such as pens, chess pieces, bottle stoppers, drawer knobs, chair spindles, salt/pepper shakers. They are also great for people who are just starting with woodturning. Many models also come with bed extensions to give you the option of spinning longer objects.

-

Midi Wood Lathe

This is the most common size used by hobbyists and serious woodworkers. They house more horsepower and more turning capacity. They have between 1 to 3 horsepower motors and can turn stock larger than 12 inches thick. A midi wood lathe is great for turning bowls, chair and table legs, baseball bats, lamp stands, and other medium size objects.

-

Full-Size Wood Lathe

This industrial full size wood lathe is designed for large commercial use. They occupy a dedicated corner in the workshop. The engine of these machines range between 3 to over 5 horsepower. This gives them the ability to latch onto and turn larger stock. A full-size wood lathe can turn stock over 40 inches long and over 15 inches thick. They are suited for turning huge workpieces such as decorative objects, long table legs, and other furniture pieces.

In general, for the average woodworkers a midi, mini, or even micro wood lathe would be the best choices. These carry enough power to spin a ton of objects at reasonable sizes and are priced to not break the bank. Ultimately, what you plan on creating with your lathe, will be the main factor for you in deciding which is the most suitable type or size.

The Art of Wood Turning

The purchase of the lathe and corresponding tools are the two initial costs for turning. After you have those it is all about your time and the cost of blanks. Often you can find lots of wood for free if you look in the right places. Downed trees, hardware store scrap piles, and even firewood can be a cheap way to furnish your practice blanks. You might even look up local tree removal companies. For the savvy woodturner these resources can become a gold mine. Maple, Cherry, or Walnut are great for learning. Avoid soft woods like pine until you get more experience.

Be resourceful, but do not waste your time on crappy wood. You may be surprised to find out how little wood you need if you go for a mini lathe. Turning pens and other smaller items is a great place to start. Find out what types of wood and what size blanks are most accessible in your area. Wood turning clubs are a great place to find resources.

Kinds of Wood You Can Turn on a Lathe

Hardwoods are the best for beginners, but an experienced woodturner can work with most green and naturally dried wood. Pressure treated wood and other woods treated with chemicals are not good because part of the wood you put on the lathe will be turned to dust in the air. Wood with knots and splits are not good as pieces of wood may break off while it is spinning causing a major hazard.

Wearing a ventilator and face shield is important no matter what kind of wood is on the lathe. Other safety equipment is available. It can be a dangerous tool, but doing some research and speaking to a professional about good safety habits while operating a lathe can mitigate those risks.

Things You Can Create on a Lathe

There are a lot of possibilities in turning and no shortage of things to make on a lathe. Salt and pepper shakers, bowls, spindles, and table/chair legs are among the most popular. Most lathes will be better suited for some things on that list than others. Everything from the size of the lathe to its speed settings and horsepower will determine if a certain lathe is best for a particular job.

Turning bowls, cups, and other useful household items is always popular as the items create value within the home. Spindles, ornate furniture, all kinds of toys, tables and just about anything else you can think of can be made on these things given some time and ingenuity.

For example, the mini wood lathes are becoming very popular with the rise of specialty writing pens. A midi wood lathe with longer capacity and higher speeds would be needed for baseball bats or spindles. If you find you have access to large blocks of wood and you want to make bowl then need a large swing bed and lower speeds. Woods are at your disposal you can look up how best to utilize those blanks and buy a lathe that fits right into your local wood supply. The best art is driven by passion. To get your best work you need to find items you are passionate about then start in your search for the best wood lathe on the market.

The Pleasure of Wood Carving Lathes

The experience of turning wood on a lathe is unlike anything else in the shop. Feeling the sharpened tools shear layers off of a long plank of wood quickly and with such precision is very gratifying. The lines and effects take shape before your eyes. Wood is cheap and easy to find for free. These handy tools have been turning a renewable resource into useful and beautiful objects for a millennia.

Overall, wood lathes are always a popular selection for displays and demonstrations. The speed at which the wood spins around and the dramatic way strips of wood and chips going flying through the air is exciting and fun to watch. Also, there are techniques that allow beginners make projects that they can be proud of with a library of advanced methods to keep even the most diligent students busy practicing new techniques for a long time. If you are a woodturner share with us some of your work in the comments section.

Bottom Line

Consider what features you need most and prioritize your budget. As you can see, some of the top woodworking lathe reviews included some useful accessory to help you get started out of the box. So if you are new to wood turning, it will be good to have such tools to experiment with and then build your way from there. Or, if you’ve been turning for a while then maybe something more up to date, easier to use without all the belts and pulleys, would be a better choice. Though, the best wood lathe for you also depends on the swing capacity and the required speed for your projects. After all, we hope with our best woodworking lathe, detailed comparison tables, and comprehensive guides, you will find yourself more confident towards choosing the most suitable wood turning machine.