We may receive a commission for products purchased through the links on our site at NO additional cost to you.

Have you ever wanted to create a small project but the wood you have is just too thick? A wood planer could be the answer for you. A wood planer can take a piece of wood and you put it through the planer and it comes out the other side thinner. Although you may need to pass it through a few times, eventually it comes out the thickness you need. Finding the best wood planer can be a difficult process. Using our unbiased best planer reviews, comparison tables, and guides can assist you in finding which is the best thickness planer most suitable for you. Comparing only the most reliable models in the market, you’ll be able to find the best benchtop planer and learn more about different features.

[go_pricing id=”best_planers”]Best Wood Planer Reviews

1. Dewalt DW735X Benchtop Planer

This planer features dual edged three knives, delivering 30% longer knife life and easier replacements. It runs on 15 amps with a powerful 20,000 RPM motor, allowing for a cutterhead speed of 10,000 RPM. It can handle wider materials with larger cuts.

Has two different speeds for controlling the feed speed, optimizing your cuts per inch at 96 or 179 CPI. The chip ejection assist will vacuum the wood chips away from the blades and into the exhaust system of the machine. This helps to reduce chips getting stuck in the blade and reduces snipe on the wood.

Has two 19¾ inch cast aluminum base. The turret depth stop is exceptionally large allowing resets to be quick and easy. It can complete a depth cut up to 1/8 inch deep. It can handle wood that is as wide at 13 inches and as thick as 6 inches.

Pros:

- A reliable planer, great for beginners and professionals alike with two speed gear box.

- It can be used with different types of wood whether soft or hard woods, delivering accurate cuts with every pass.

- With an automatic carriage lock and two rubber rollers, marks and knicks on the wood are diminished greatly and help to produce fine quality cuts.

- Fan-assisted chip ejector vacuums chips off of the cutter head with a dust port of 2.5 and 4 inches.

- Comes with infeed and outfeed tables and an extra set of knives.

Cons:

- Weighs 92 pounds. It is rather heavy for a portable thickness planer which may not make it ideal for those who would need to transport it or move it around the workshop.

- It’s also really loud during operation.

2. Cutech 40200H-CT Thickness Planer

This planer seems to have it all. It has 4 guide posts, 2 screw posts, a snipe lock for the cutterhead, and internal gears that are used for height adjustment. It features a repeat cut option to eliminate resetting the cutter depth each time you want to do the same cut on multiple boards.

The spiral cutterhead has 26 high speed steel (HSS) knives. The double sided cutterhead allows you to flip it when the blades get nicked or dull to save on purchasing new blades each time they dull out. With 26 knives and a maximum cutting depth of 1/8 inches, the cutters do not have to work very hard to trim the wood. It also helps to reduce marks and snipe on the wood.

The dust chute can be connected to a shop vac to help collect the dust made from the planer, with a dual dust port of 2.5 and 4 inches. It runs on a 15 amp motor with 23,000 RPM and can feed wood up to 13 inches wide and 6 inches deep.

Pros:

- Has 14 x 14 inches infeed and outfeed tables. The set up is quick and easy, generally taking less than 15 minutes time.

- This planer is great for soft or hard woods with a cutterhead speed of 9,000 RPM.

- It does not bog down with use over an extended period of time and does not heat up with prolonged use.

- The anti snipe locking mechanism truly works.

- Clearly marked depth gauge helps to make fine adjustment to the cutting depth allowing you to cut more accurately.

Cons:

- It does not have a good dust collection system and still leaves quite a bit of mess to clean up. This also causes big wood chips to get stuck in the cutterheads, damaging the wood and the cutterhead.

- Since it is a spiral cutterhead rather than true helical cutterhead, the blades can sometimes leave unwanted marks on the boards.

3. JET JWP-208HH Wood Planer

This stationary planer is built into a rather large ground table made of cast iron. It is a great choice for bigger projects and serious woodworkers. It has a large infeed and outfeed tables measuring 25¾ x 30 inches and are also made out of cast iron. The large hand wheel allows you to adjust the cutter depth easily to make precise 1/16 of an inch adjustments for fine cuts and up to 3/32 inches.

A cutterhead speed of 5,000 RPM with a feed rate of 24 to 31 feet per minute (FPM). It features 92 knives that are four sided so that you can flip your blade 3 more times before replacement.

The motor is rather intricate with a 3V belt transmission and an induction motor that runs on 5 horsepower. It has a 5 inch dust collection port that you can attach a shop vac in order to collect the wood chips, avoiding any mess or jams inside the planer.

Pros:

- A helical cutterhead planer with carbide inserts, great for any type of wood.

- It is a very quiet planer for its size making it great for workshop spaces.

- Has a maximum capacity of 20 inches width and 8 inches depth. However, the snipe is very limited with this planer, even when cutting smaller boards.

- Two-speed gear box with automatic chain tension, allows you to adjust the feed rate easily.

- Built for quality and durability, it will last you for a very long time.

Cons:

- Installation and set up are not very easy regardless of experience level.

- This planer is not for beginners. It is meant for advanced users who have a great deal of experience with wood planers.

4. WEN 6550T Benchtop Planer

This planer utilizes a two high carbon steel blade system. The blades can be rotated in order to minimize the purchase of new blades and keep your cuts sharp. The handle has a rubber grip for easy and comfortable adjustments.

Adjustments can be made within 0 to 3/32 inch accuracy. The infeed and outfeed tables are 12½ x 6¾ inches and they are foldable which can make for easy storage as well as easy travel. The planer has a dust collection port that can be attached to any traditional shop vac. The port can accommodate 2 inch hoses.

It runs on a 15 amp motor and can cut more than 18,000 cuts per minute (CPM) at an approximate feed rate of 26 feet per minute (FPM). It can accommodate boards up to 12½ inches wide with a thickness of 6 inches. You can mount it to a table or a stand using the pre-drilled holes in the base.

Pros:

- Every pass made with this planer is managed with a cutterhead speed of 8,500 RPM.

- One of the best portable thickness planers with a weight of 70 pounds. It’s a great planer for beginners and is very easy to learn on.

- Best value thickness planer, the price is comparable to most beginner planers on the market today.

- Changing the blade is quick and easy so there is not much downtime.

- The manufacturer provides great customer service when calling with technical issues.

Cons:

- It has a problem with the bearings going out after just a few times of being used.

- The handles and the entire right side of the planer are held together with only two screws which is a bit weak.

5. Porter Cable PC305TP Thickness Planer

This planer runs on 15 amps. It also has a quick change cutter head with two knives. The blades are reversible to allow for longer lasting blades before needing a new blade. This helps to reduce costs by having to change blades less frequently. Simply rotate then you are good to go.

It is made from a highly durable solid steel that makes it last a long time. It can run up to 8,000 RPM providing up to 16,000 cuts per minute (CPM). The infeed and outfeed tables fold in for easy storage and transportation. It can handle smaller pieces of wood, however, there will be about 1 inch of snipe on each side.

It can cut materials that have been glued together with ease. That makes it perfect for any type of project. It can handle wood up to 12½ inches wide and 6 inches thick. It is a self feeding planer so there is little effort to actually planing the wood.

Pros:

- It has a maximum cutting depth of 3/32 inches.

- This planer works great for wood that needs tarnish or paint removed.

- It straightens boards quickly and easily regardless of the damage to the wood or bed to the wood.

- This planer is versatile and great for beginners and experts alike.

- Best planer for the money, it is rather easy to set and put together. Most of the effort is cleaning the grease off of it.

Cons:

- The blades on this planer tend to dull out or chip rather quickly requiring frequent replacement.

- With a weight of only 65 pounds. It is complicated to control and reduce vibrations on this planer if you do not mount it to a table or stand.

6. Makita 2012NP Wood Planer

This 12 inch planer can plane wood up to 12 inches wide and 6 inches thick. It has an adjustable depth stop so that you can make multiple identical cuts or repetitive cuts. It can cut multiple kinds of wood with ease. This planer features simple controls for the user to learn on or for the more intricate projects to be easier.

It runs at 8,500 RPM and 15 amps. It makes up to 17,000 cuts per minute (CPM) and feeds at 28 feet per minute (FPM). The cutter system on this planer has two knives. The blade change is quick and easy. It comes with a detachable tool box to keep all of the added tools in.

This planer also features a 3 inch hose dust collection system that can be purchased separately to make clean up a breeze. Weighs only 62 pounds, it is a compact planer for easier storage making it great for the smaller workshop or for transporting to a work site.

Pros:

- Makes 1/8 inch deep cuts. It can plane any type of wood with no issues at all. This means it can handle soft or hard woods with ease.

- It is amazing at planing wood that has been glued together or woods that have tarnish or paint on it. Also, suitable for short and long boards alike.

- Low noise planer compared to other models, it is easy to use for beginners and easy to learn on.

- The blades are designed with quality and last quite a long time, even after multiple passes of different types of wood.

- Has four post design with diagonal cross support to increase stability.

Cons:

- The blades are rather expensive to replace.

- The feed rollers also doesn’t last very long and may require replacement.

Best Thickness Planer Comparison Chart

| Product/Feature | Input | Power Source | Speeds | Dust Port | Weight | Dimensions |

|---|---|---|---|---|---|---|

| Dewalt DW735X | 120V, 15A | Corded | 2 | 2.5/4 In. | 92 lb. | 24 x 22 x 18.8 In. |

| Cutech 40200H-CT | 120V, 15A | Corded | 1 | 2.5/4 In. | 88 lb. | 26 x 16 x 23 In. |

| JET JWP-208HH | 230V, 27A | Corded | 2 | 5 In. | 765 lb. | 44 x 28 x 23 In. |

| WEN 6550T | 120V, 15A | Corded | 1 | 2 In. | 70 lb. | 23.5 x 24 x 19 In. |

| Porter Cable PC305TP | 120V, 15A | Corded | 1 | N/A | 65 lb. | 23 x 15 x 17.7 In. |

| Makita 2012NB | 220V, 15A | Corded | 1 | 3 In. | 62 lb. | 30.4 x 19 x 15.8 In. |

How to Choose the Best Planer (Ultimate Guide)

If you are interested in expanding your collection of tools, make sure you already own the essentials. One of them is a planer. A new machine or a tool is usually a large investment. Hence, ensuring that it is also a good one is very important. Since there are certain factors which need to be taken into account, we are presenting you with a guide which will help you get the best woodworking planer, completely suitable for your needs.

Generally, it is always smart to go a bit beyond what you actually need. What we mean by that is you should go with a planer that would take a bit more work than you planned on doing. So, if at any time you decide to take on a bigger project, you know that your planer can take it. There are several important details you should pay attention to:

-

Motor & Power

You should definitely look into how powerful the motor is. As a general rule, electric motors usually come in two variants induction motors and universal motors. Induction motors are more robust and durable, they are usually used in heavy duty industrial machines. While universal motors are more light and compact, which are better suited for portable machines.

Many indoor woodworkers choose 5 or 6 amps machines, but you may need greater power depending on your projects. After all, you want a planer that can handle any kind of wood, not just pine. A 15-amp (1800-watt) motor is really powerful even on hard maple and oak, so you do not have to worry about the performance of it. The power determines how fast the stock removal is and how smooth the finish is.

-

Material Capacity

Planing width and thickness indicates the maximum width and thickness of the boards that you can feed through a planer. Well, a width capacity of 12 or 13 inch planers are usually enough to satisfy the needs of an average woodworker. You should also take the maximum height into consideration, however, a thickness capacity of 6 inches is usually enough.

Keep in mind, these are the maximum capacities that can be fed, so you can also pass narrow boards through your planer depending on your project. Generally, if you know you regularly use wider lumber, then you should opt for a more heavy-duty planer with much greater width capacity, such as 15 inch planers, 20 inch planers, or even more.

-

Cutting Capacity

The maximum cutting depths of wood thickness planer usually range from 3/32 inch to 1/8 inch, the better the planer, the more it will be able to shave off in one pass. You are not required to use the maximum depth of cut available since this would increase the likelihood of snipes. However, the maximum depth of cut is an indicator of the planer’s ability.

-

Cutterhead

Knives are what actually shapes the wood, so they are one of the most important details you need to take into account. The number of knives, are they disposable, or able to sharpen, quality, sharpness, knife life, wear out speed – all of these should influence your decision. A higher number of cutters will provide a smoother finish.

We recommend choosing planers with reversible knives, so you can flip them over and use them again when one edge gets dull, effectively doubling their lifespan. Nearly all straight-knife cutterheads feature double-edged knives (self-indexing knives). Knife sharpness will save you a lot of time after planing because you would not need to sand the wood as much since the surface would be almost scallop-free.

The type of the cutter head is also relevant. You can choose straight knives, however, spiral or helical cutterhead is what we recommend. Especially helical cutters, since it reduces chipping and produces less noise, however, it is more expensive and more difficult to sharpen. On the other hand, straight knives are more cheap, it’s easier to feed boards through them, and easier to sharpen them too. Usually, most benchtop thickness planers comes with two or three straight knives.

Finally, carbide blades are recommended over high speed steel (HSS), since they are resistant to corrosion, oxidation, and abrasion which results in longer knife life and reduces the number of times you need to change them. Usually, straight knives are made with high speed steel (HSS). While helical and spiral cutterheads are made with carbide. Additionally, you can also opt for changing the cutterhead type of your planer if you wish to in the future. However, replacing the cutterhead to a different style may not be supported by the manufacturer can void your warranty.

-

Speed Rate

Knives of thickness planers rotate at high speed to chip off wood from the surface of the boards. The higher number of blades the higher the stroke count. Also, material removal rate depends on the speed in which these blades are rotated and the revolutions per minute (RPM). However, speed is not the only indication of quality, as with some stock materials slower strokes produce better results and vice versa. Some bench-top planers come with two speeds, between which you can alternate depending on the type of wood you plane and what result you expect.

The cutter head speed is measured in cuts per inch (CPI), also, sometimes it’s measured in cuts per minute (CPM). This is relevant to determine how smooth the surface would be after planning. Each one of these affects the duration of the process as well as the quality of the final result.

In addition, feed rate is also important because it determines how fast you can get the job done. This is indicated with feet per minute (FPM). However, it’s always better to focus on the cutter head speed over feed speed. Usually, wood thickness planers have higher speeds than bench planers.

-

Stops & Gauges

Stops are useful little features, which help you apply the same thickness settings to different boards. However, it is not perfect and often does not do what it should because it tilts the cutterhead, which results in different thickness between different boards. Since it is not a perfectly functional feature, you should not base your decision entirely on it. It is a feature you can live without.

Gauges, on the other hand, show how much wood will be removed in one pass, so you would not go overboard and make a tear or a snipe. Again, useful, but if you were to choose between better knives but no gauges, or gauges but lower quality knives, we recommend choosing the former. However, gauges are usually there.

-

Snipe & Scallop

Snipes are deeper cuts that occur at the beginning and end of the boards after they go through a planer. These are far from problematic and there are several ways to combat them, but they can be annoying. For this reason, some planers have a mechanism which locks the cutterhead in place and prevents snipes. The size of the infeed and outfeed tables also play a role in reducing snipes. In addition, the amount of rollers and feed speed all help to prevent the scallop effect. After all, usually some light sanding is enough to remove any unwanted effects.

-

Dust Collector

This detail is very important primarily because of the health risks when working with wood. While planing, there is a lot of chips which make a mess unless you have a way of collecting them. So, a dust collector port would be a nice addition to the planer you choose.

-

Accessories & Additional Functions

Some of the additional details that may be appealing to you are:

- Directing chip ejection on either side of the tool for your convenience.

- Granite infeed and outfeed tables which will never warp the wood.

- Extension tables which could be folded up for storage.

- Detachable toolbox.

- Longer cord so you could put the planer anywhere in your workshop (but longer cords are more difficult for transportation).

These would be the most important technical details regarding return on investment (ROI) for planers. Of course, the higher the price, the better these features are, but that is not a given. You can find high-quality planers in every price range. Again, keep in mind that prices of hand planers and stationary surface planers should not be compared since these are completely different machines. It is best to decide on a wood planer based on your needs and try to fit it in your budget. If you listen to our advice, you will not make a mistake.

Everything About Thickness Planers

A planer is an essential tool of every woodworking project since it is directly involved in shaping the material you will use to make whatever you have imagined. In any creative process, having the right tools is essential. Same goes for woodworking, where your tools are indeed your best friend. It is very important to know what your options are, what could be useful to you and why you should immediately get certain tools. Because of that, we are introducing to you everything you need to know about thickness planers.

What is a Wood Planer?

A thickness planer is one of many essential woodworking tools, primarily used for trimming boards to the thickness you need. You may wonder if there are other tools you have that can do the same, but what is specific for a planer is that the desired thickness is consistent throughout the length of the board and it makes both surfaces flat with a fine finish.

A planer goes by different names such as a thickness planer or a surface planer. It is mainly used for trimming down the thickness of the wood while flattening and smoothing the rough surfaces. For these reasons, many fellow woodworkers could not imagine working without a planer. We are certain you realize how a planer could benefit you too, but first let us introduce you to the various types of planers. As a result, you will also be able to understand our thickness planer reviews and their characteristics.

Is there More than One Type of Planers?

Yes, there are several types of wood planers. Generally, we divide them into manual planers, electric planers, and stationary large planers. Now, to determine the type which suits your needs, you need to think about three things:

- What kind of projects will you be working on?

- How much space do you have in your workshop?

- How much money are you willing to spend on it?

If you do not have a lot of space and you do not want to splurge, a manual planer is for you. It is quiet affordable, very simple to use, and fits comfortably in your hand. Since it is small in size, you can take it anywhere. If your projects require small and detailed work, a manual planer is good for you. It does not need batteries or cords since it is powered only by your hand and strength.

However, if you want to be more efficient and faster, invest in an electric planer which has more power. You can choose between the corded or the cordless versions with batteries. They take a bit of practice to learn how to control them, however, they allow you to accomplish a lot of work in a short period of time with little effort.

Finally, stationary or benchtop planers are for you if you have space and bigger projects to work on. They are used to plane wood boards to your desired size and thickness. Due to their strength and power, you can feed them larger boards than other planers. Of course, for a hobbyist or a woodworking enthusiast, these machines are usually too much.

How Does a Planer Work?

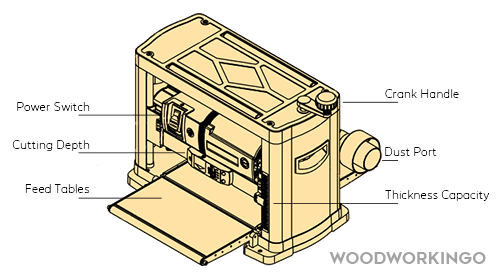

A thickness planer typically consists of:

- A cutter head which holds the blades cutting the wood.

- Rollers which pull the board into and through the planer.

- An adjustable table used to set the desired thickness.

After you feed the planer with lumber, the head grabs the board and starts pulling it through the machine and the planed board comes out of the other side. As for the thickness of the lumber, most benchtop planers can plane 12-inch wide stock, but of course, there are other options such as some stationary planers which can process much wider stock. Generally, the bigger planer in size, the wider stock it can plane.

How to Use a Planer?

As with any other machine, there are many kinds and models of thickness planers. It is very important to read instructions and remember them before planing lumber. Also, if you are a beginner, it would be a good idea to practice with some boards you have lying around just to get the grip on how the machine works and what you should pay attention to. This will prevent possible disasters which could happen if you jump right into a fresh piece of wood you actually plan using in a project. However, there are some general guidelines on using a thickness planer.

First and foremost, for this machine to ‘do its thing’, you need to make sure that one surface is perfectly flat. This surface is used as a reference by the machine so it could make a parallel surface, along with a flat finish. If a board does not fulfill this requirement, you can flatten one surface with a jointer, and then run it through the planer as previously described.

You may also be interested to check our list of the best wood jointers.

Of course, as with any machine, make sure you do not put your hands or fingers near the cutter head. While feeding the board, do not hold it underneath since there is a risk of your hand being pulled into the planer. Safety equipment is a must: safety goggles, gloves, and dust protection are necessary, and we also recommend some hearing protection since the machine is extremely loud.

Benefits of a Benchtop Planers

Whether you are a hobbyist or a professional, a thickness planer is a useful machine to add to your collection of tools. Forget about fancy, expensive, planed boards. You can do everything yourself with a thickness planer.

- It allows you to buy stock in bulks or from the lumberyard and make it the thickness you need for your project. Because the wood is not planed, it is cheaper and you can spend far less money on a big project.

- You will stop stressing about finding a piece of wood exactly the right size. Days spent in the shop looking for the right piece are over.

- More than often you will find a piece of wood which has waves or bad edges which you need to fix. So, it is better to buy or find any piece of wood and tailor it to your own needs, as a pro would do.

- Also, recycling lumber or adapting unused boards left over from a previous project is now possible. You will not have excess stock and unused wood anymore since you will be able to use every last piece for some other project.

- Finally, you will actually save time by investing in a thickness planer. You probably tried achieving the same effect with other tools (sand belts, jointers, hand planers, etc.). However, all these techniques are time-consuming and require a lot of skill, but the result is not even close to what you can achieve with a thickness planer.

So, if you would like to save money and time by trimming, shaping, and planning your own boards, we highly recommend saving up for a benchtop planer and adding it to your tools as soon as possible. It will open a whole new range of possibilities and inspire you for your next woodworking project.

Handheld Electric Planers vs. Benchtop Planers

Since one of the most popular planer types are benchtop planers and handheld electric planers, we decided to make a comparison between the two and give you more details about each type.

If you are not running a lot of stock, stationary closed stand planers are unnecessary and you are probably trying to decide if a benchtop planer or a handheld electric planer would be a better option for you. This comparison will help you weigh all the possibilities and determine what will best fit your needs.

-

Handheld Electric Planers

A handheld electric planer is used for the same purposes as any other planer but in more small to medium sized projects. They are especially useful for detailed work. There is a distinction, however, between manual planers and electric planers. The former is powered by your hand and strength, while the latter runs on electric energy or batteries. You should keep in mind the differences between these two types as well.

A handheld planer is for more fine work when details are important. Power handheld planers are a bit different in a way that they are more for imprecisely removing thickness from the board, but detailed work needs a lot of practice. An electric planer is used on wood which needs to be clamped into one place so it would not move. You then put the planer above the wood and push forward.

Another difference is that you cannot as easily achieve the same thickness through the whole length of the board with a handheld electric planer, as you can with a benchtop planer. It takes a lot of skill and even more time to achieve the same result when it comes to getting the right thickness. A thickness planer would be the right choice for small detailed type of projects. To learn more check our best power planers post.

-

Benchtop Planers

A benchtop planer, smooths wood surface and helps you in shaping boards and achieving the right thickness. This type of planer is especially popular among woodworkers who take on medium to large sized projects as it is more powerful than a manual or an electric planer, but not as large and expensive as heavy-duty surface planers.

Next, the way in which you use these planers is different. You feed the boards into the benchtop planer, so you actually only bring the wood to it. As a result, working with benchtop planers proves to be more efficient. You will get everything done faster, so it is more convenient. Also, it is more comfortable for you since you just need to stand there and feed the boards into the planer. For handheld power planer, then the difference in the speed still exists. By checking our benchtop planer reviews you will be able to know about these features.

Finally, types of work you can do with these planers are a crucial difference. We have already mentioned trimming the thickness and that a benchtop planer is a better option for that. It is also more suitable for shaping wood for larger projects, shaping wider boards, and getting everything done more quickly or on a larger amount of stock.

Making Your Choice

There are some matching features of both an electric and a benchtop planers. If you need to be very mobile, it would be important to you that your tools are too. Both of these planers are portable, so if you often work onset, both would suit your needs. Since they are smaller in size you can move them around your workshop and put them wherever you want. Handheld electric planers are a bit more convenient but the difference is not so crucial. Also, both types of planers are more budget-friendly than stationary planers. The truth is, there is a wide price range for both types. We would say the price range of the two is similar.

These were all the similarities and differences between electric and benchtop planers. All in all, benchtop planers are said to be more versatile and faster. But it all comes down to the type of work you need them for. You see that there are some similarities between the uses of each tool, but still, one is always better than the other when it comes to a certain type of work. We hope these pieces of information and advice are useful to you and that you will be satisfied with the choice you make regarding the next tool you plan to buy.

Bottom Line

Finding the best rated planer doesn’t have to be a complicated task. It is all a matter of what you are going to use the wood planer machine for. If you are a hobbyist, the best wood planer may not be a large piece of equipment. You may need the best benchtop planer for all your projects. Regardless of what your purpose for a wood planer is, you want to get one that is the best thickness planer you can get with your budget. This means paying attention to how many knives the cutterhead has and how many times they can be flipped. What type of stand can it be placed on or does it have its own. Determine what you need and you will be able to find the best planer most suitable for you from our comparison of wood planer reviews.